20 years ago, I had one of those cheap brinkmann smokers and it worked very well. Of course being thin sheet metal, it eventually rusted out. I finally got another one a few years back and couldn’t get it hot enough. There are tricks and hacks to fix that but I couldn’t see putting the time and effort into the cheap thing and since I have an abundance of hickory, oak and cherry here, I decided to just make a wood fired smoker. After getting some scrap water heaters, I got the idea to make a smoker out of them. I got three 40 gallon units and we had a small under the counter unit. I got one of the water heaters working by putting a new heating element in it and we’re using it in the house. The other two 40 gallon units, plus the small one became the offset smoker with horizontal & vertical chambers like the one below.

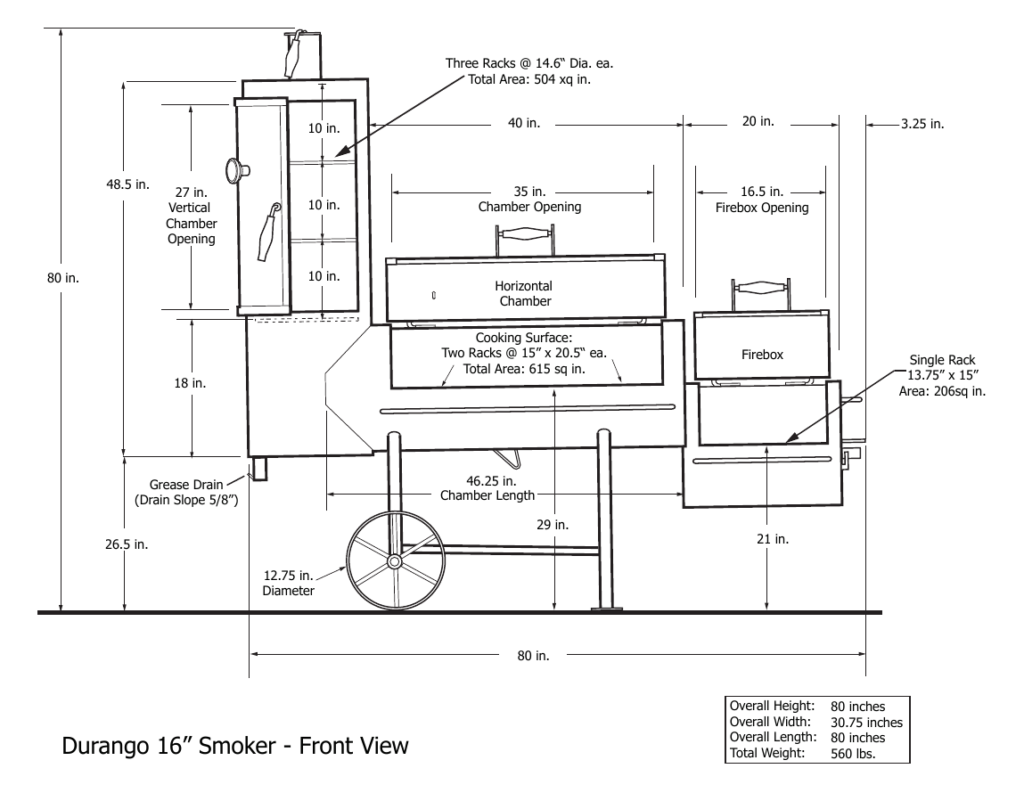

The above smoker is a Durango 20 inch model that goes for a mere $2300.00 though it is made of schedule 40 pipe which has a wall thickness of about 1/4 inch. Water heater tanks are considerably thinner. While looking at retail smokers, I stumbled on some drawings giving the dimensions for the 20 inch model and a 16 inch model that’s no longer produced. My water heater tanks are 18 inch diameter so I just split the difference. Below is Yoder’s 16 inch Durango model.

They also have an end view with dimensions.

Using the drawings from Yoder, along with some calculations for openings and smoke stack, it was time to go to work. I started by cutting one end of the vertical tank out, flipping it over and welding it back on so that both ends would be domed rather than one being concaved. Next, I moved to coping the two big tanks together.

What should I call it? Durango 18 Lite?

Next I welded the small tank on for the firebox.

All the doors were cut out with a cut off disk in the angle grinder. You can see the first cut in the above pic.

All doors cut and a magic balancing act. Good thing it wasn’t windy that day. Both the fire box and vertical chamber have fittings facing down which gave me a little flat surface which is how it can stand upright like that. I stayed close to it so I could catch it in case a breeze did come.

The round grates for the brinkmann smokers will work for my vertical chamber. I still need to buy three new ones and install them. As such, I haven’t been able to use that chamber yet.

I cut, bent and welded flat bar on to make door flanges. Aside from supplies, flat bar, latches and thermometers were the only things purchased.

Hand made hinges from old truck clutch linkage

I capped off the hinges for the vertical tank with weld so they shed rain.

Horizontal doors installed

Just need handles/latches and grates.

More homemade hinges.

Cooking and fire grates made. I also use expanded metal grating to go on top of the rebar fire grate.

First burn

Stack with flow damper

Damper adjustment

Latches and handle installed. I need more thermometers. The right one is a proper one and the left is just a quick read meat thermometer setting in the hole.

Latch and firebox loading door. I didn’t bother with any kind of fancy vent adjustment. I simply crack the door. One inch seems to maintain it pretty well

One of my smokes. Boston Butt is what I do most as it’s cheap. It was also the first thing I tried as it’s forgiving.

That red edge is called the smoke ring.

I smoke our ribs so that we can pull the bones right out and eat them with a fork or make a rib sandwich. Likewise with the Butt Roasts. I can pull the bone right out and the different muscles pull right apart or fall apart. There’s one round muscle about 1 1/2 – 2 inches in diameter and 6 inches long that meat smoking competitors call the Money Muscle. Just melts in your mouth.